Introduction:

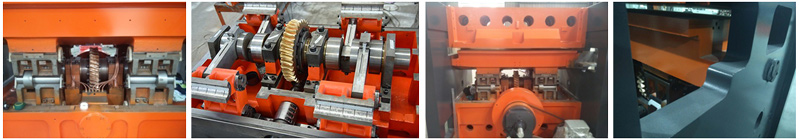

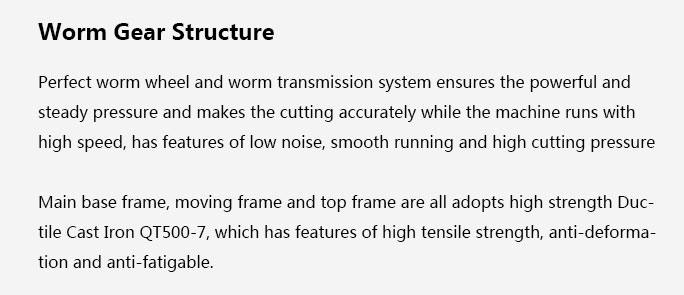

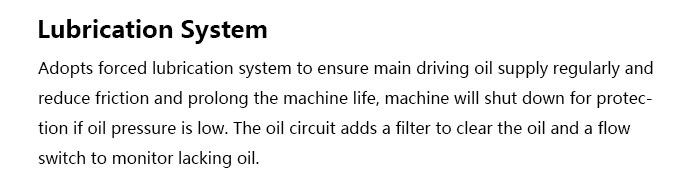

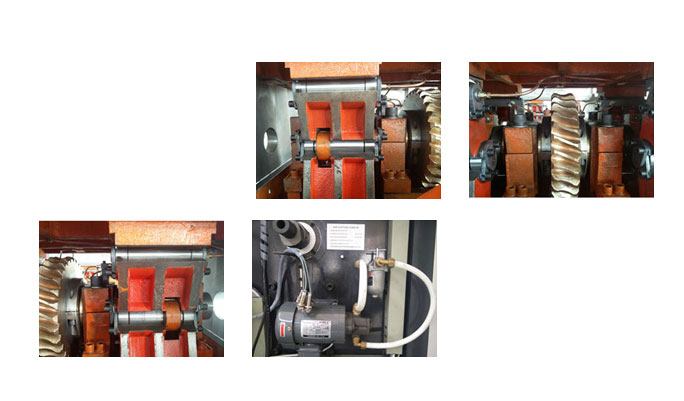

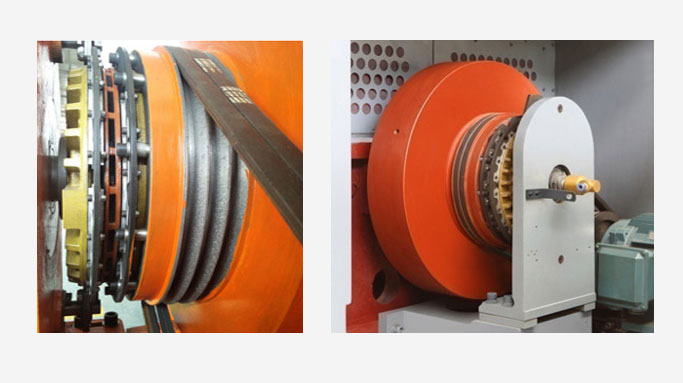

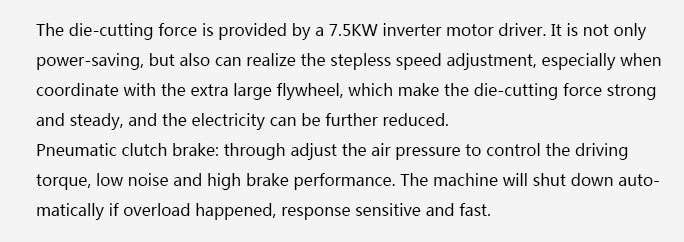

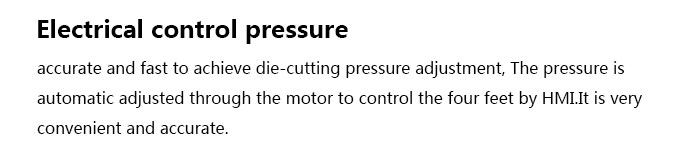

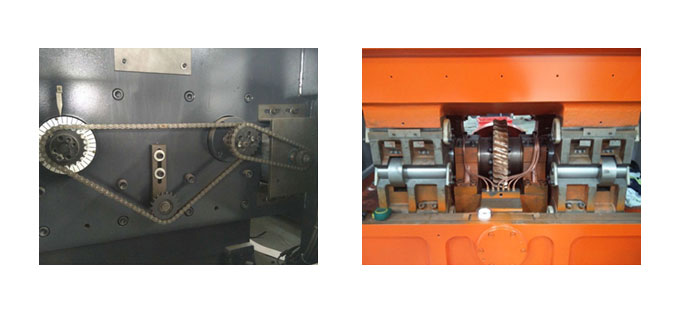

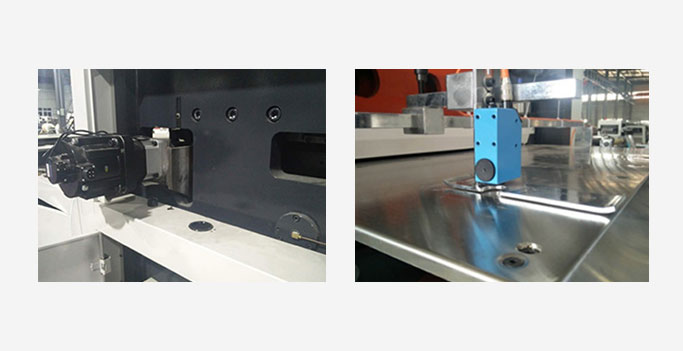

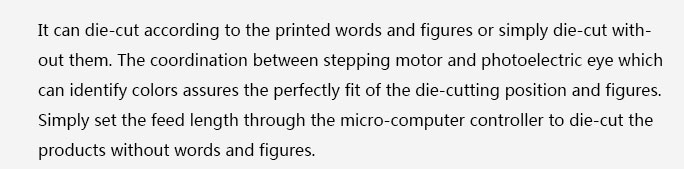

FD series automatic roll die cutting machine based on international advanced technology, has a high stability, high safety performance, high precision of the finished product, it’s widely used in paper packaging, such as paper box and so on. It adopts micro-computer, human-computer control interface, servo positioning, alternating current frequency converter, automatic counting, manual pneumatic lock plate, photoelectric correcting deviation system, electromagnetic cluth, centralized oil lubrication, overload protection and distinctive gearing. So it gurantees smooth operations of returning paper and feeding paper, precise positioning and oderly withdrawing. All the key parts and controls of the machine are imported. Such installation can realize the machine in steady pressure, precise positioning, smooth moving, saftey and reliability.

Technical Specification

| Model | 970x550(640) | FDZ1080x640 | FDZ1200x640 | FDZ1400x780 |

Customized |

| Max Cutting Area | 940x520mm(610) | 1050x610mm | 1160x610mm | 1350x750mm | |

| Max Paper Widht | 950mm | 1060mm | 1180mm | 1380mm | |

| Cutting Precision | ±0.10-0.2mm | ||||

| Paper Gram Weight | 120-400g/㎡ / 120-600g/㎡ | 120-600g/㎡ | |||

| Production Capacity | 100-180 times/min | 80-130 times/min | |||

| Air Pressure Requirement | 0.6Mpa | ||||

| Air Pressure Consumption | 0.25m³/min | ||||

| Max Cutting Pressure | 150T/280T | 280T | |||

| Max Roller Diameter | 1600mm | ||||

| Stable Running Power | 11KW | 11KW | 14KW | 14KW | |

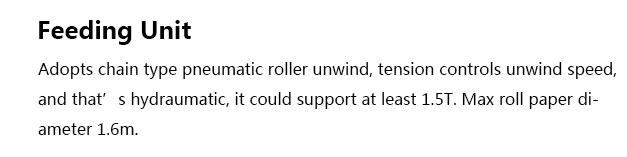

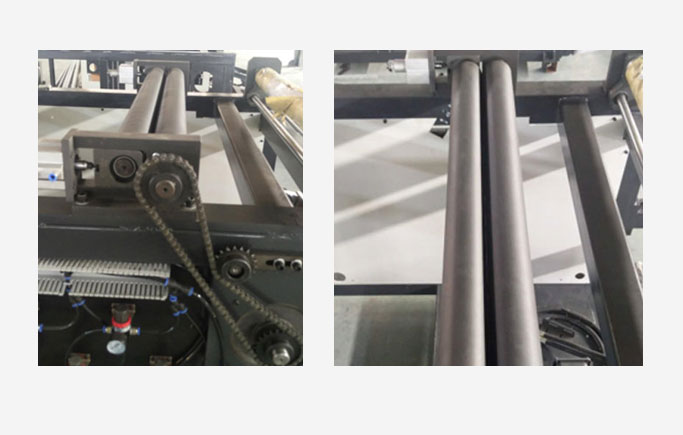

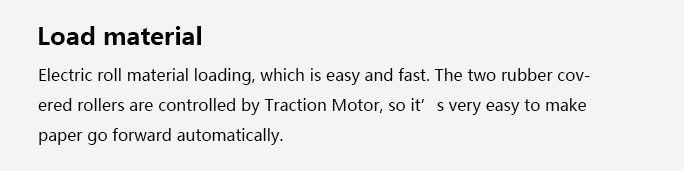

Main structure

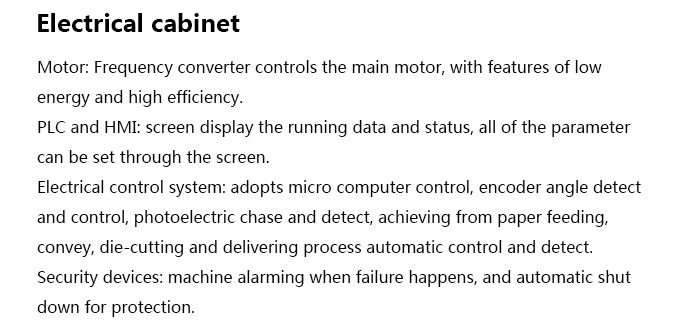

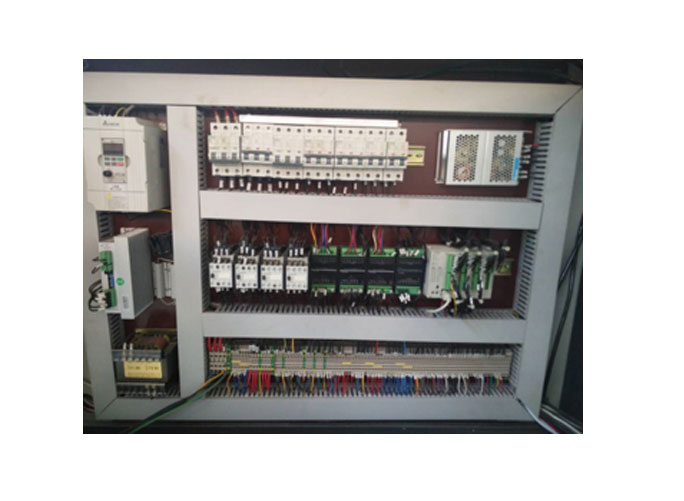

Electric Configuration

|

Stepper Motor |

China |

|

Pressure adjusting motor |

China |

|

Servo driver |

Schneider(France) |

|

Color Sensor |

Sick(Germany) |

|

PLC |

Schneider(France) |

|

Frequency converter |

Schneider(France) |

|

All other electrical parts |

Germany |

|

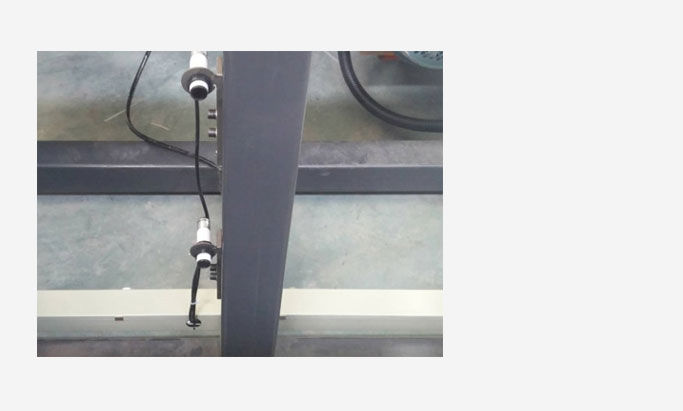

Photoelectric switch |

Germany |

|

Main air cylinder |

China |

|

Main Solenoid valve |

AirTAC (Taiwan) |

|

Pneumatic clutch |

China |

|

Main bearings |

Japan |

CI Flexo (Central Impression Flexographic) printing machines are sophisticated devices used primarily in the packaging industry for high-quality, high-speed printing...

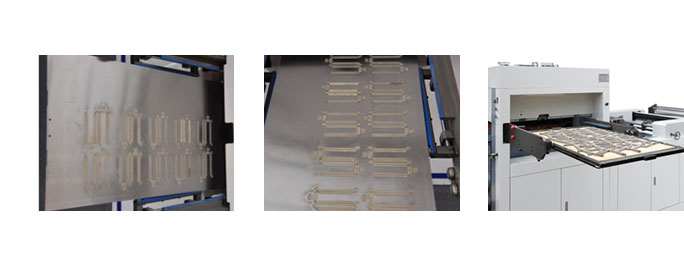

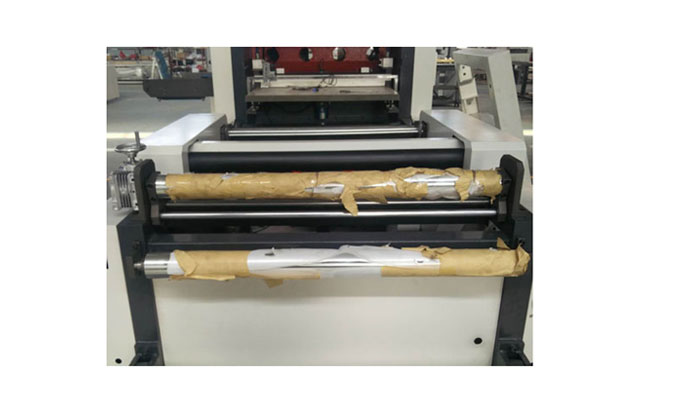

Roll Die Cutting Machine is an advanced printing equipment widely used in the paper packaging industry. It uses advanced computer control technology to cut a large n...

What is Flexography? Flexographic printing (Flexography) is a high-speed, multi-colour, high-efficiency flexible printing technology, which is widely used in packagi...

The principle of flexographic printing involves the use of a flexible printing plate, usually made of rubber or photopolymer material.

Please contact with me directly