Introduction:

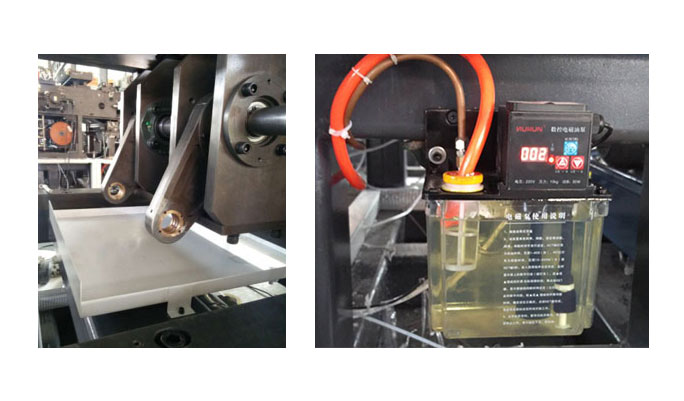

FDC series automatic roll punching machine based on international advanced technology, it’s widely used in paper cup fan products. It adopts micro-computer, human-computer control interface, servo positioning, alternating current frequency converter, photoelectric correcting deviation system, centralized oil lubrication.

The equipment is suitable for paper thickness of 150-350 gsm roll paper for rapid and precise punching, collecting and stripping at the same time, can be applied to paper cups, paper bowl, paper plate etc.

|

Model |

FDC850 |

FDC920 |

FDC1000 |

FDC1200 |

|

Max Paper Width |

850mm |

920 |

1000 |

1200 |

|

Cutting Precision |

±0.20mm |

|||

|

Paper Gram Weight |

150-400g/㎡ |

|||

|

Production Capacity |

280-380times/min |

280-380times/min |

280-330times/min |

260-300times/min |

|

Air Pressure Requirement |

0.6Mpa |

|||

|

Air Pressure Consumption |

0.25m³/min |

|||

|

Weight |

3.5T |

4T |

4.5T |

5T |

|

Max Roller Diameter |

1500mm |

|||

|

Total Power |

10KW |

10KW |

10KW |

12KW |

Smaple

|

|

|

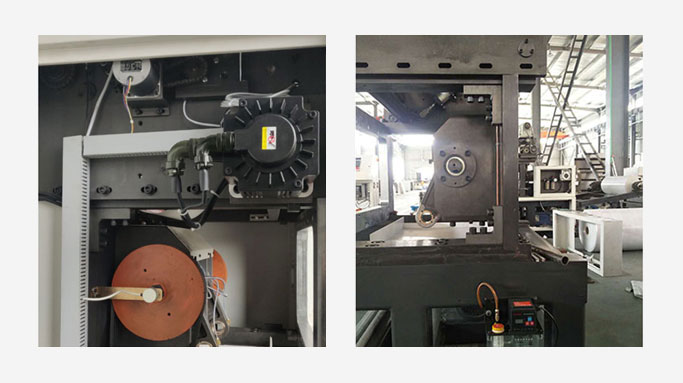

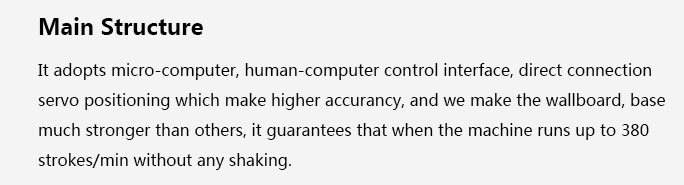

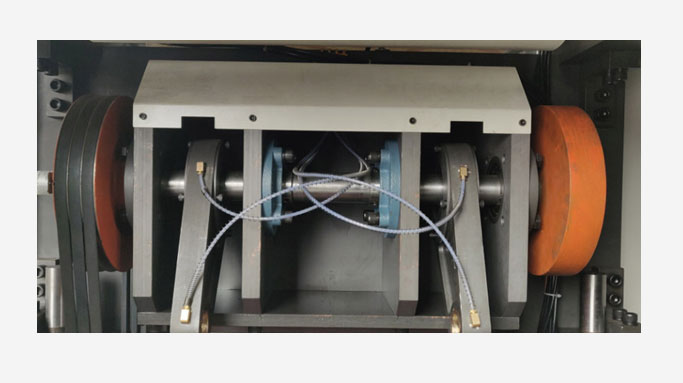

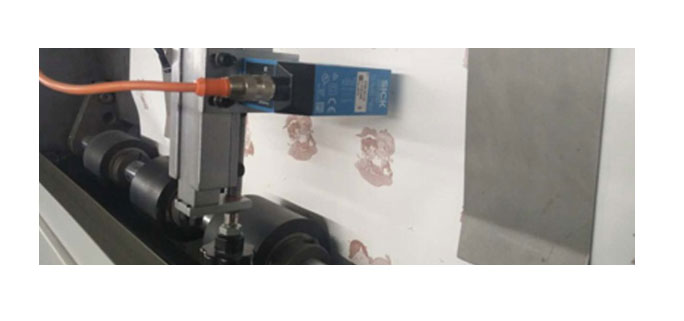

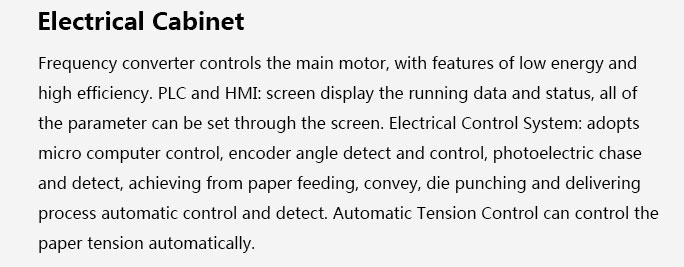

Main Structure

Printing is a fundamental process in manufacturing, packaging, and publishing industries. Among the various printing techniques available, three main processes domin...

What is a Flexo Printing Machine Used For? A Comprehensive GuideFlexographic printing, commonly known as flexo printing, is a highly versatile printing method widely...

In today’s fast-paced manufacturing and packaging industry, efficiency and precision are critical. One of the key pieces of equipment that helps companies achieve th...

The printing industry offers a variety of technologies to meet diverse production needs, with flexographic printing and digital printing being the two most prominent...

Please contact with me directly