Flexographic vs. Digital Printing: Key Differences and Benefits

The printing industry offers a variety of technologies to meet diverse production needs, with flexographic printing and digital printing being the two most prominent methods. While each has its own advantages, they are suitable for different applications based on speed, cost, quality, and material compatibility.

This article explores the key differences between flexographic and digital printing, and highlights the advantages of flexographic presses in high-speed, high-volume production environments.

1. Technology and Process Comparison

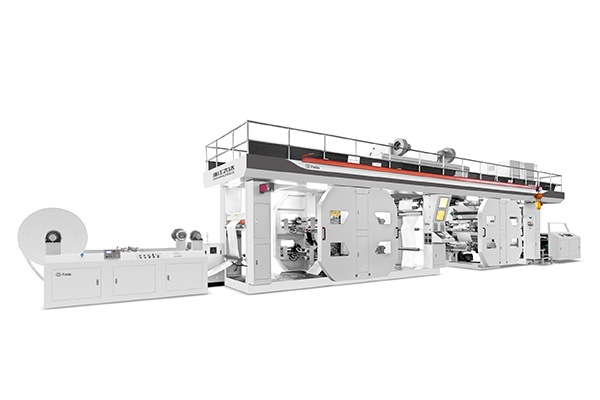

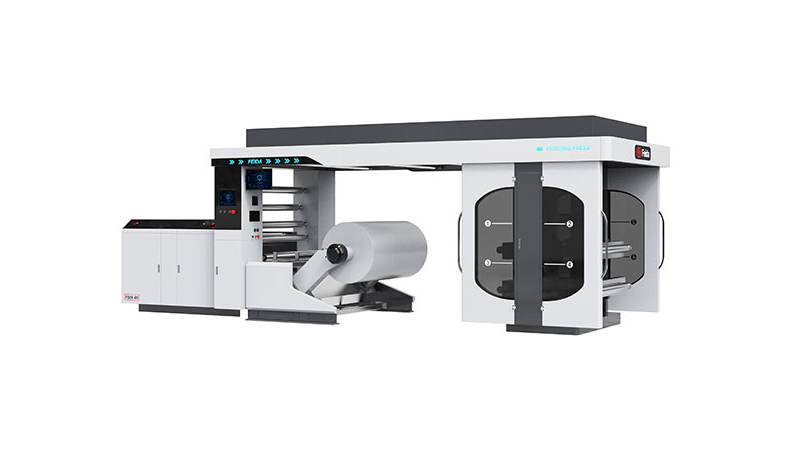

Flexographic printinga

Uses flexible relief plates mounted on a rotating drum.

Ideal for high-volume printing due to high production speeds.

Supports a wide range of materials, including plastic film, paper, aluminum foil, etc.

Capable of high-precision multi-color printing (1 to 10 colors).

Has automated features such as paper feeding, drying, and automatic shutdown for increased efficiency.

Digital printing

No plates required; direct inkjet using inkjet or laser technology.

Best suited for short runs, custom printing, and variable data printing.

Lower setup costs, but higher unit costs for high-volume printing.

Limited material compatibility compared to flexographic printing.

2. Key benefits of flexographic printing

A.High-speed production

Feida flexographic presses excel in high volume production, with speeds up to preferred for packaging, labeling and industrial printing.

B.Cost-effective for high volume production

Lower unit costs for bulk orders due to faster production and more durable plates.

Automated features (e.g., automatic metering, positioning) reduce labor costs.

C.High-quality, consistent output

Flexographic printing offers high resolution and the most vibrant colors, perfect for high-end packaging and branding.

3. When to choose digital printing?

While flexographic printing dominates in mass production, digital printing is better suited for:

Small batches and prototyping

Personalized or variable data printing

Quick turnaround jobs where plate setup is uneconomical

4. Why Feida Flexographic Printing Presses Stand Out

Feida's advanced flexographic printing solutions offer:

Versatile operation (single/double-sided, offset, gravure)

Automated and efficient (reduced waste, minimal human intervention)

High speed and accuracy (up to **10-color printing**, clear registration)

Wide material compatibility to meet the needs of different industries

Conclusion

Flexographic printing remains the first choice for high-speed, large-scale production, especially in the field of packaging and label manufacturing. Digital printing, while flexible, lacks speed and cost-effectiveness for mass orders.

For companies seeking high-performance, automated and versatile printing, Feida Flexographic Printing Presses offer the best solution - combining speed, quality and cost-effectiveness to meet the needs of industrial scale.