What is a Carton Forming Machine?

In today’s fast-paced manufacturing and packaging industry, efficiency and precision are critical. One of the key pieces of equipment that helps companies achieve these goals is the Carton Forming Machine. This innovative piece of equipment automates the process of forming flat board or corrugated boxes, significantly increasing production speed and consistency.

What is a Carton Forming Machine?

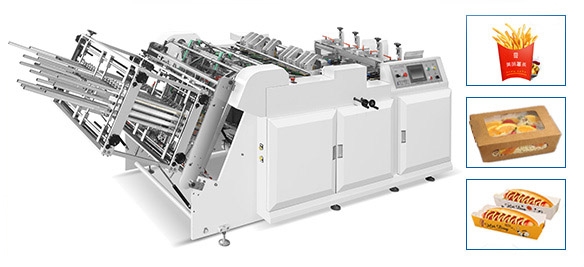

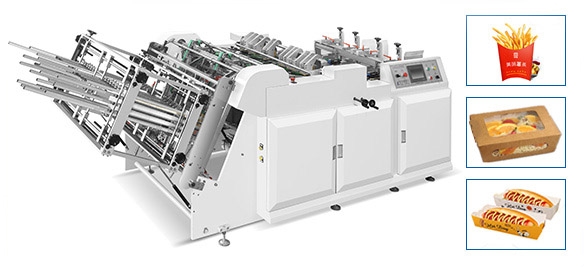

A Carton Forming Machine is an automated packaging equipment designed to efficiently convert flat cardboard or corrugated sheets into fully assembled cartons, boxes, or containers. Using precision folding, gluing, or sealing mechanisms, it streamlines the packaging process by eliminating manual labor while ensuring consistent shape, structural integrity, and high-speed production. Ideal for industries like food packaging, e-commerce, and logistics, this machine enhances productivity, reduces material waste, and maintains uniform quality in carton fabrication.

How a Carton Forming Machine Works

The Carton Forming Machine is designed to convert flat board into fully formed cartons or containers for packaging. The process includes:

1. Feeding Flat Carton Blanks – The machine receives pre-cut flat carton blanks.

2. Folding and Gluing – The machine uses precision servo motors to fold the carton into shape and glue it in place as needed.

3. Finished Carton Ejection – The fully formed carton is then ejected and conveyed to the next stage of the packaging line.

This fully automated system eliminates manual operations, reduces errors, and ensures consistent quality across all cartons.

Key Features of Modern Carton Forming Machines

1. High-Speed Forming

Designed for rapid production, modern carton forming machines can assemble hundreds of cartons per hour. This high-speed operation streamlines production lines, making it ideal for industries with large packaging needs, such as food and beverage, e-commerce, and pharmaceuticals.

2. Precise Servo Motor Control

An advanced servo motor system ensures precise folding and gluing, allowing the machine to easily handle cartons of various sizes and designs. This precision is particularly important for odd-shaped containers such as those used for lunch boxes in the fast food industry.

3. Consistent Quality and Durability

Automation ensures a consistent shape and structure for each carton, reducing waste and improving overall packaging quality. The machine's robust construction guarantees long-term reliability, even in demanding production environments.

4. Versatile Design for Multiple Applications

Whether you need a standard shipping box, food container, or custom-shaped carton, the carton forming machine can be adjusted to accommodate different sizes and materials, including paperboard, cardboard, and corrugated.

Industries that benefit from carton formers

Food and Beverage – for assembling food-grade cartons, takeaway containers and beverage holders.

E-commerce and Logistics – for rapid prototyping of cartons to meet high shipping demands.

Pharmaceutical – for creating safe and uniform packaging for medical products.

Consumer Goods – for efficient packaging of electronics, cosmetics and household goods.

Conclusion

A carton former is an essential investment for businesses looking to increase packaging efficiency, reduce labor costs and maintain high quality standards. With features such as high-speed operation, precise servo motor control and versatile design, this machine will revolutionize the landscape of modern production lines.

Whether you are in the food packaging, logistics or retail industries, integrating a **carton former** into your workflow will significantly increase productivity and ensure consistent, professional-grade packaging results every time.

Do you need advice on choosing the right **carton former** for your business? Let us help you find the perfect solution for your packaging needs!