The Three Main Printing Processes: A Focus on Flexo Printing Machines

Printing is a fundamental process in manufacturing, packaging, and publishing industries. Among the various printing techniques available, three main processes dominate the market: flexography (flexo), offset, and digital printing. Each method has unique advantages depending on the application. In this article, we will explore these three processes, with a special focus on flexo printing machines —their features, benefits, and applications.

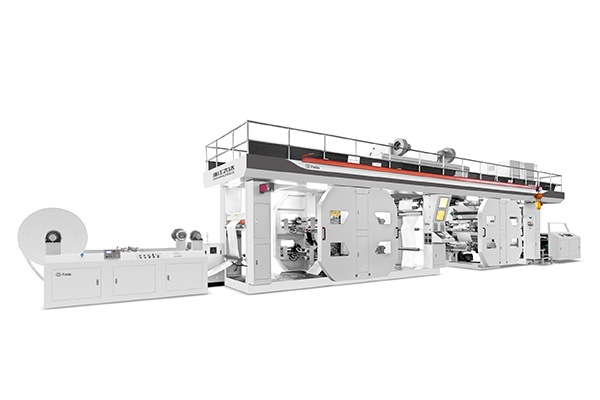

1. Flexography (Flexo) Printing

What is Flexo Printing?

Flexography, commonly known as flexo printing, is a high-speed, roll-fed printing process that uses flexible relief plates. It is widely used for printing on non-porous materials such as plastic, film, foil, and paperboard.

Key Features of Flexo Printing Machines

Flexible Plates: Made of rubber or photopolymer, these plates adapt well to uneven surfaces.

Fast Production: Ideal for large-volume printing due to high-speed capabilities.

Versatility: Can print on a variety of substrates, including labels, packaging, and corrugated cardboard.

Eco-Friendly Ink: Often uses water-based or UV-curable inks, reducing environmental impact.

Applications

Packaging:Food bags, shrink sleeves, and beverage labels.

Labels: Self-adhesive labels for consumer products.

Corrugated Boxes: Printing on cardboard for shipping and retail packaging.

2.Offset Printing

What is Offset Printing?

Offset printing is a traditional method where ink is transferred from a plate to a rubber blanket and then onto the printing surface. It is best suited for high-quality, large-scale paper printing.

Key Features

High Image Quality:Produces sharp, clean prints with excellent color consistency.

Cost-Effective for Bulk Orders:Economical for large print runs.

Uses Metal Plates: More durable than flexo plates but less flexible

Applications

Books & Magazines

Posters & Brochures

Newspapers

3.Digital Printing

What is Digital Printing?

Digital printing eliminates the need for plates, transferring digital files directly to the printer (e.g., laser or inkjet). It is ideal for short runs and customized prints.

Key Features

Quick Turnaround: No plate setup required.

Variable Data Printing: Allows customization (e.g., personalized packaging).

Lower Setup Costs: More economical for small batches.

Applications

Marketing Materials (flyers, business cards)

On-Demand Publishing

Custom Packaging & Labels

Why Choose Flexo Printing Machines?

Flexo printing machines are the preferred choice for packaging industries due to their:

High-speed production

Ability to print on diverse materials

Cost-efficiency for long runs

Superior print quality on flexible substrates

Conclusion

Flexo, offset, and digital printing are the three main printing processes. While offset printing excels in high-detail paper printing and digital printing offers customization, flexo printing machines dominate in packaging and label production. Understanding these three main printing processes helps businesses select the best method for their needs.

For industries requiring durable, high-speed, and versatile printing, flexo printing remains a top choice.

Would you like recommendations on flexo printing machine manufacturers? Let me know how I can assist further!