What is a Flexo Printing Machine Used For? A Comprehensive Guide

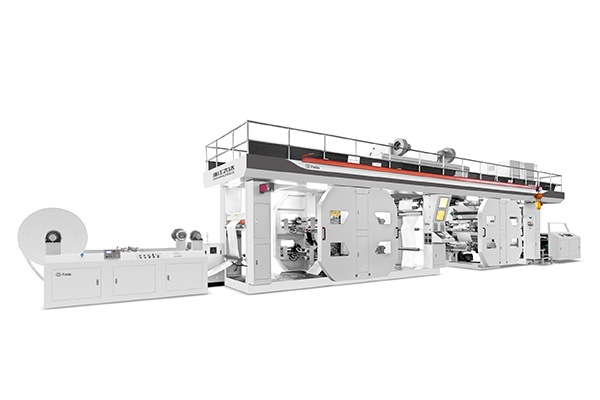

What is a Flexo Printing Machine Used For? A Comprehensive GuideFlexographic printing, commonly known as flexo printing, is a highly versatile printing method widely adopted across multiple industries. The flexo printing machine stands out for its exceptional adaptability, capable of performing various printing operations including single- and double-sided printing, offset printing, and even gravure printing simultaneously. This advanced technology delivers superior print quality on diverse substrates while incorporating automated features that significantly enhance production efficiency.

Fei Da Unmatched Versatility of Flexo Printing Machines

Modern flexo printing machines integrate multiple functions to streamline the printing process:

Multi-directional Printing - Handles single- and double-sided printing with precision

Hybrid Printing Capabilities - Combines flexographic, offset, and gravure techniques

Automated Operation - Features paper feeding, automatic metering, high-speed positioning, drying systems, and automatic shutdown

Material Compatibility - Supports various substrates including plastic films, paper, aluminum foil, and more

Key Performance Features

1. High-Speed Production

With machine speeds reaching 200m/min, flexo printers enable mass production without compromising quality. This high-velocity operation makes them ideal for large-volume orders and time-sensitive projects.

2. Customizable Color Options

Flexo presses offer flexible color configurations:

1 to 10 color sets available

Precise color registration for vibrant, consistent results

Quick changeover between jobs

3. Superior Print Quality

Achieves high-resolution printing effects

Meets stringent quality requirements for premium products

Maintains sharpness and clarity even at high speeds

4. Automated Efficiency

Reduces labor requirements by up to 60%

Minimizes human error through precision automation

Enhances overall cost-effectiveness

Industry Applications

Flexo printing machines serve diverse sectors with their adaptable performance:

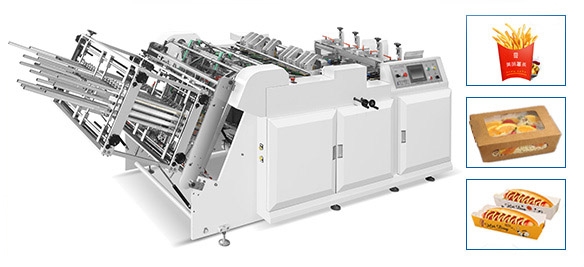

1. Packaging Industry

Flexible Packaging: Stand-up pouches, shrink sleeves

Labels & Stickers: Premium product labeling

Aluminum Foil Printing: Pharmaceutical and food packaging

Corrugated Boxes: High-volume shipping solutions

2. Consumer Goods

Food Wrappers: FDA-compliant food-safe printing

Beverage Packaging: Cartons and flexible laminates

Household Products: Decorative films and tissues

3. Industrial Applications

Adhesive Tapes: Branded and functional printing

Technical Films: Specialized industrial applications

Technical Advantages

Material Versatility: Handles everything from delicate films to rigid substrates

Eco-Friendly Options: Compatible with water-based and UV-curable inks

Precision Engineering: Micro-meter registration for flawless prints

Energy Efficiency: Optimized drying systems reduce power consumption

A flexo printing machine is used for high-speed, versatile printing on various flexible materials like packaging films, labels, and corrugated cardboard.

Why Choose Flexo Printing?

The Fei Da flexo printing machine represents the pinnacle of printing technology, combining:

Unmatched production speeds(200m/min)

Exceptional print quality (high-resolution output)

Complete automation(from feeding to finishing)

Broad material compatibility(films, foils, papers)

For businesses seeking to enhance their printing capabilities while optimizing production costs, flexo printing technology offers the perfect balance of performance, quality, and efficiency.

Interested in integrating flexo printing into your production line?Contact our experts for personalized machine recommendations tailored to your specific requirements.