Carton Automation Equipment Solutions for Small Food Factories: Enhancing Efficiency with Carton Erecting Machines

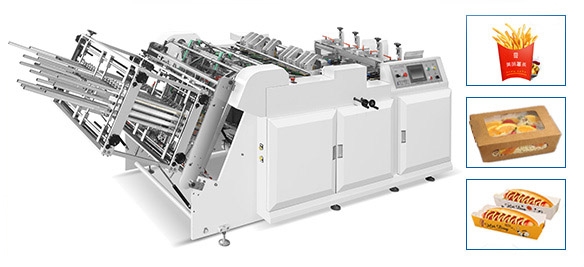

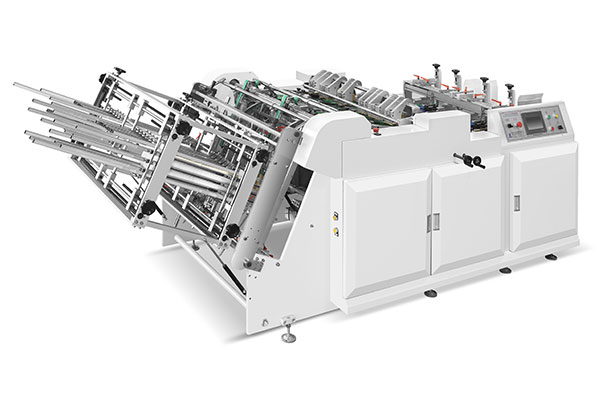

In today’s competitive food industry, small and medium-sized food factories face growing challenges in packaging. With increasing product variety and smaller batch sizes, the packaging process has become more complex, demanding flexible and efficient solutions. This is where Carton Erecting Machines (also known as Paper Box Forming Machine) play a crucial role—streamlining production while maintaining precision and cost-effectiveness.

I.The Packaging Challenges for Small Food Factories

Small food manufacturers often deal with:

Frequent product changes – Different box sizes and styles for burgers, fries, takeaway meals, etc.

Lower production volumes – Unlike large factories, they cannot rely on mass-production economies of scale.

Higher labor costs – Manual folding and gluing of cartons are time-consuming and inconsistent.

Strict hygiene & safety standards – Food-grade packaging requires reliable, contamination-free automation.

II.How Carton Erecting Machines Solve These Problems

Feida Paper Box Forming Machine automates the entire carton setup process, offering:

1. Fast, Flexible Production

Quick mold changes to switch between different box types (burger boxes, snack trays, lunch containers).

Adjustable settings for various materials (cardboard, corrugated paper, food-safe paperboard).

2. Precision & Consistency

Servo motor-controlled forming ensures every box is identical, reducing waste.

PLC programming allows for complex folds and custom designs.

3. Labor & Cost Savings

Reduces dependency on manual labor, cutting long-term operational costs.

Automatic stacking and counting minimize handling errors.

4. Compact & Scalable for Small Factories

Unlike bulky industrial machines, compact Carton Erecting Machine fit limited floor space.

Modular designs allow upgrades as production grows.

III.Choosing the Right Machine for Your Needs

When selecting a Paper Box Forming Machine, consider:

Output Speed – Match it to your daily production volume.

Material Compatibility – Ensure it works with your preferred paperboard thickness.

Ease of Operation – Look for user-friendly PLC controls and quick-adjustment features.

After-Sales Support – Technical service and spare parts availability are critical.

Conclusion

For small food factories navigating the challenges of diverse product lines and small-batch production, a Carton Erecting Machine is an indispensable investment. By Feida automating carton forming, businesses can achieve higher efficiency, lower costs, and consistent packaging quality—key factors in staying competitive in the fast-moving food industry.