Roll Die Cutting Machine: A Comprehensive Overview

A roll die cutting machine, also known as a rotary die cutting machine, is a crucial piece of equipment in various manufacturing and packaging industries. This machine is designed to cut, shape, and form materials like paper, cardboard, and plastic into precise shapes using rotary dies. Here's a detailed look at how roll die cutting machines work and their applications:

How Roll Die Cutting Machines Work

1. Material Feeding: The material, often in the form of a continuous roll, is fed into the machine. This is usually done using a feeding system that ensures the material is fed evenly and accurately.

2. Rotary Dies: The core component of the roll die cutting machine is the rotary die. These dies are cylindrical tools with cutting blades that rotate and cut the material as it passes through the machine. The dies are custom-designed to create specific shapes and patterns.

3. Cutting Process: As the material moves between the rotary dies, the cutting blades press down onto the material, cutting it into the desired shapes. The precision of the cutting process is determined by the accuracy of the rotary dies and the alignment of the material.

4. Ejection and Collection: After cutting, the finished products are ejected from the machine. They are typically collected on a conveyor belt or in a collection bin, ready for further processing or packaging.

5. Adjustments and Controls: Modern roll die cutting machines come with advanced controls that allow for adjustments in speed, pressure, and die alignment. This ensures consistent quality and precision in the final products.

Types of Roll Die Cutting Machines

- · Flatbed Rotary Die Cutting Machine: This type features a flat cutting bed with rotary dies that move in and out of the material. It's commonly used for high-precision cutting tasks.

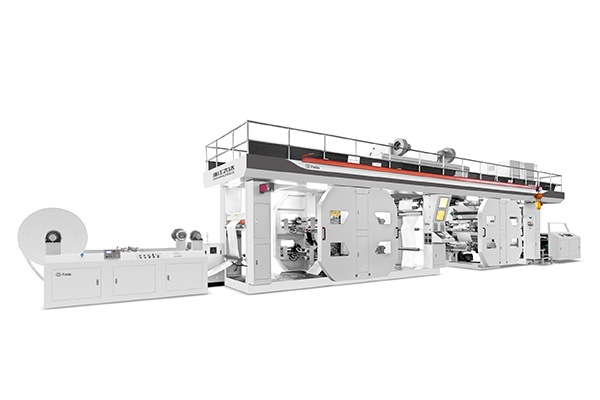

- · Inline Rotary Die Cutting Machine: In this setup, the die cutting process is integrated with other production processes, such as printing or laminating. It’s ideal for high-speed production lines.

- · Intermittent Rotary Die Cutting Machine: This machine cuts the material in intervals, allowing for greater control over the cutting process and suitability for complex designs.

- · Continuous Rotary Die Cutting Machine: This type maintains a continuous feed of material and is used for high-volume production with consistent cutting requirements.

Applications of Roll Die Cutting Machines

- 1. Packaging Industry: Roll die cutting machines are extensively used to produce packaging materials like boxes, cartons, and blister packs. They ensure accurate and efficient cutting of packaging components.

- 2. Label and Tag Production: The machines are ideal for cutting labels and tags from rolls of material. This includes adhesive labels, product tags, and more.

- 3. Printing Industry: In printing, roll die cutting machines are used to create shaped prints, promotional materials, and customized products.

- 4. Automotive and Electronics: They are used to cut and shape materials for automotive parts and electronic components, providing precise and consistent results.

- 5. Textile and Fashion Industry: Roll die cutting is used for cutting fabric and materials into specific patterns for garments, accessories, and other textile products.

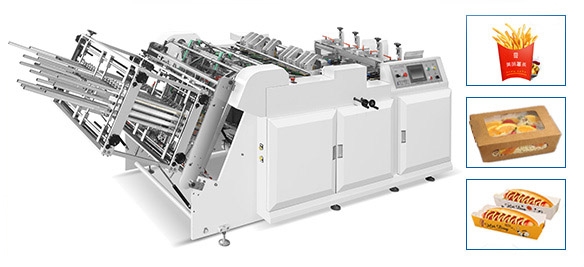

Feida Machinery Roll Die Cutting Machine

The FD series automatic roll die cutting machine leverages advanced international technology to offer high stability, precision, and safety. It is widely used for paper packaging, such as paper boxes. Features include a micro-computer control interface, servo positioning, AC frequency converter, automatic counting, manual pneumatic lock plate, photoelectric correction system, electromagnetic clutch, centralized oil lubrication, and overload protection. With all key parts and controls imported, it ensures smooth operation, precise positioning, and reliable performance.

Maintenance and Considerations

- Die Maintenance: Regular inspection and maintenance of rotary dies are essential to ensure cutting quality and machine longevity.

- Material Handling: Proper feeding and alignment of the material are crucial for achieving precise cuts and preventing machine jams.

- Safety: Operators should follow safety guidelines to avoid accidents, especially when handling cutting dies and moving parts.

Conclusion

Roll die cutting machines are essential tools in modern manufacturing and packaging industries. Their ability to efficiently and accurately cut a variety of materials makes them invaluable for producing high-quality products. By understanding their operation, applications, and benefits, businesses can leverage these machines to enhance productivity and maintain a competitive edge in their respective markets.